A laser cutter is a perfect tool for several projects. It provides the ability to create all types of things and handle many projects. From creating a simple box to engraving intricate details in plastic or wood or building all types of 3D objects.

Most people know that the first step is finding the right laser cutter, which is possible by looking at boss laser on youtube. Once the right laser is found, learning how to use it is key. Keep reading to learn more about using a laser cutter here.

Laser Cutter Defined

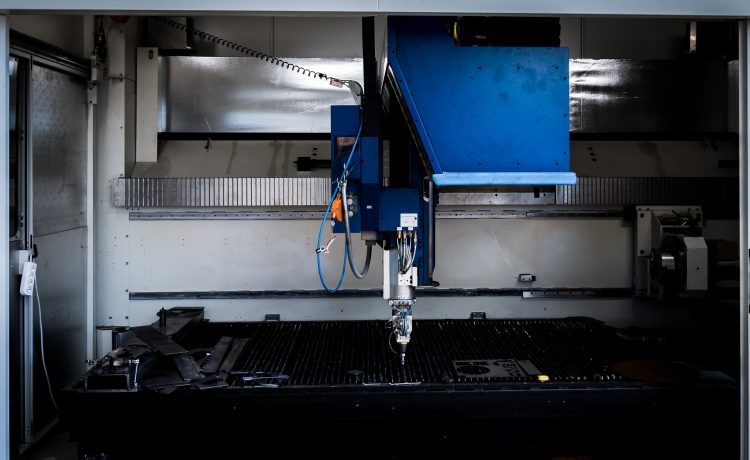

Laser cutters are machines controlled by a computer that use a laser beam to engrave or cut materials in precise or intricate patterns. Lasers are basically highly amplified, focused light. The laser beam will cause the material to locally vaporize, melt, or burn. The type of material that can be used with a laser is dependent on the laser type and the power of the machine.

The word laser is actually an acronym. It means Light Amplification by Stimulated Emission of Radiation. This technology was developed during the 1960s.

Different Types of Laser Cutters

Today, it is possible to find several types of laser cutters. The information here focuses on CO2 and gas lasers specifically. This is because this type of laser is the most common one used by small businesses and hobbyists. There are other types of lasers, too. For example, crystal and fiber lasers are traditionally used for industrial purposes.

With a CO2 laser cutter, it is possible to engrave or cut several types of non-metallic materials, including leather, textiles, acrylic, paper, wood, and more.

How Do Laser Cutters Operate?

With a CO2 laser cutter machine, the laser beam is created in a tube that is filled with CO2 gas. Next, thanks to the presence of lenses and mirrors, the laser beam will be directed to the head of the laser and focused on the surface of the material. The electronically controlled motors have to move the laser heat to engrave or cut the shape desired into the workpiece or material. The shape is determined by an input file, which may be a raster or a vector image.

When the laser comes in contact with the material, a very small portion of it will be heated for a short period of time. This results in the material vaporizing, burning, or melting.

Finding the Right Laser Matters

When it comes to getting the desired results from a laser cutter, there are several factors to consider. Be sure to take time to find a laser cutter that can handle the job or project that needs to be done. This is the only way users can feel confident they will get the desired results.

Remember, there are a lot of options available for sale today. It is important to read reviews and see these machines in action to ensure the right one is found and purchased. Being informed is the best way to find the right laser cutter for the job.